- About Company

- Company Profile

-

Product Gallery

- HVAC Instruments

- Portable Humidity & Temperature Data Loggers

- CO2 Transmitter

- Rotronic HF3 Series

- RH And Temp Transmitter

- Humidity Controller cum Indicator

- Rotronic HF6 Series

- Rotronic HF4 Series

- Air Velocity Transmitters Series E+E75

- Air Velocity Transmitters Series E+E66

- CO2 Transmitter (Series EE80 & EE82)

- Duct Mounted CO2 Transmitter

- Digital Anemometer

- Air Flow Capture Hood

- Digital Thermo Hygrometer (HTC-1)

- Air Velocity Transmitter

- Humidity & Temp. Data Logger

- RH & Temp. Scanner (Paper Less Chart Recorder)

- Humidity & Temperature Transmitter

- SETRA Diff. Pressure Transmitter

- Calibration Master Instruments

- Moisture Transmitter

- Pressure Transmitters

- Temperature Instrument

- Cold Chain Temperature Logger

- Humidity/Temperature Transmitter

- Bimetallic Temperature Gauge

- RTD and Thermocouple

- Head Mount Type Temp Transmitter

- Gas Filled Temperature Gauge

- Temprature Instruments

- Higher Range Online Temperature Probe

- Temperature Gauge

- Digital Temp. Controller / Indicator

- Programable Temperature Controller

- Portable Infra-Red Thermometer

- Temperature Transmitter

- Level Instruments

- Magnehelic Gauge

- Flow Instruments

- Pressure Gauges

- Gauge Accessories

- Pressure Switch

- Calibration Instruments

- Data Loggers

- Analog Vacuum Gauge

- Potable Meter

- Air Velocity Sensor

- HVAC Instruments

- Extra Links

- Contact Us

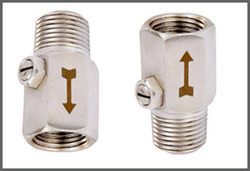

Snubber Damper

395 INR/Unit

Product Details:

- Outer Size Varies as per application and thread size

- Frequency Suited for pulsation frequencies up to 60 Hz

- Sensor Type Pressure Dampening Device

- Thread BSP/NPT, available in various sizes (commonly 1/4 or 1/2)

- Case Metallic, corrosion-resistant coated steel or stainless steel

- Measuring Range Depends on System Pressure, typically up to 400 bar

- Bourdon Tube Not applicable (dampers do not use a bourdon tube)

- Click to View more

X

Snubber Damper Price And Quantity

- 395 INR/Unit

- 1 Unit

- 395.00 - 395.00 INR/Unit

Snubber Damper Product Specifications

- Depends on System Pressure, typically up to 400 bar

- Not applicable for damper (no direct measurement)

- Viton / Nitrile / PTFE options available

- Not applicable (dampers do not use a bourdon tube)

- Maximum 400 bar (can vary by design)

- BSP/NPT, available in various sizes (commonly 1/4 or 1/2)

- Industrial

- Metallic, corrosion-resistant coated steel or stainless steel

- Mild steel (MS), Stainless Steel (SS 304/316)

- Suited for pulsation frequencies up to 60 Hz

- Pressure Dampening Device

- Varies as per application and thread size

- Pressure damping, gauge protection, hydraulic and pneumatic lines

Product Description

Owing to our expertise in this domain, we offer Snubber Dampner that is made by using quality tested required materials with the help of cost-effective technology. This item is use to shield a pressing factor sensor from harm. It directs, standardizes, and wipes out fuel pressure spikes present the fuel framework during the underlying start and start-up of a diesel motor. The delivery of this Snubber Dampner is done by us within the promised time frame.

Snubber Dampner;- we are manufacturer and supplier of Snubber Dampner in best quality.

Specification:

- Size : 1/4 to BSP/NPT

- Nominal Pressure : 0 to 1000 kg/cm2

- Temperature : Up to 120 Degrees Celsius

- Material : Body-SS316/SS304/CS other Materials Available On Request.

- Testing : 100% Pressure / Hydrostatically Tested

Superior Pressure Damping for Industrial Pipelines

Our snubber dampers are engineered to provide reliable suppression of pressure surges and pulsations in hydraulic and pneumatic systems. With customizable connections and corrosion-resistant materials, they are suitable for a broad spectrum of industrial applications. Mounting options include both inline and manifold, with the flexibility to choose end connections that fit your systems requirements. Their mechanical damping mechanisms ensure consistent performance, safeguarding sensitive gauges and equipment.

Designed for Durability and Versatility

Manufactured in compliance with IS/ISO/ANSI standards, our snubber dampers feature robust construction using mild steel or stainless steel. Surface treatments such as powder coating, nickel plating, and passivation ensure long-term resistance to corrosion. Select from seal materials like Viton, Nitrile, or PTFE to match your operating temperature and media needs. We offer a range of thread sizes and connection types to guarantee compatibility with diverse pipeline setups.

FAQs of Snubber Damper:

Q: How does the snubber damper reduce pressure surges in pipelines?

A: The snubber damper utilizes a mechanical spring mechanism or piston-type design to absorb and dampen sudden fluctuating pressures, minimizing pressure surges and vibrations. This prevents damage to gauges and other sensitive equipment, enhancing system longevity.Q: What are the mounting and connection options available for this damper?

A: Snubber dampers can be installed inline or on a manifold. End connections are highly customizable and are offered in male or female BSP/NPT threaded variants, with sizes commonly available in 1/4 or 1/2 inch, to suit different pipeline requirements.Q: When should a snubber damper be used in hydraulic or pneumatic lines?

A: Install a snubber damper whenever you need to protect pressure gauges, regulate system pressure fluctuations, or reduce pulsation frequencies up to 60 Hz. It is especially beneficial in high-pressure environments, with maximum working pressure up to 400 bar.Q: Where can snubber dampers be installed and what applications are they suited for?

A: Snubber dampers are suitable for use in industrial settings, including hydraulic and pneumatic lines, pressure damping systems, and gauge protection setups. They can be installed wherever vibration and pressure surges threaten equipment stability and performance.Q: What is the process for customizing the dampers end connection or seal material?

A: Customization can be based on application specifics. You may request end connections in preferred thread sizes (BSP/NPT) and select seal materials like Viton, Nitrile, or PTFE that align with your operating temperature and fluid compatibility requirements.Q: What benefits do snubber dampers provide to industrial pipeline systems?

A: Snubber dampers offer leak-proof performance, corrosion resistance, and effective pressure regulation. By reducing surges and vibrations, they protect downstream equipment, minimize maintenance needs, and improve the overall reliability of the system.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email