- About Company

- Company Profile

-

Product Gallery

- HVAC Instruments

- Portable Humidity & Temperature Data Loggers

- CO2 Transmitter

- Rotronic HF3 Series

- RH And Temp Transmitter

- Humidity Controller cum Indicator

- Rotronic HF6 Series

- Rotronic HF4 Series

- Air Velocity Transmitters Series E+E75

- Air Velocity Transmitters Series E+E66

- CO2 Transmitter (Series EE80 & EE82)

- Duct Mounted CO2 Transmitter

- Digital Anemometer

- Air Flow Capture Hood

- Digital Thermo Hygrometer (HTC-1)

- Air Velocity Transmitter

- Humidity & Temp. Data Logger

- RH & Temp. Scanner (Paper Less Chart Recorder)

- Humidity & Temperature Transmitter

- SETRA Diff. Pressure Transmitter

- Calibration Master Instruments

- Moisture Transmitter

- Pressure Transmitters

- Temperature Instrument

- Cold Chain Temperature Logger

- Humidity/Temperature Transmitter

- Bimetallic Temperature Gauge

- RTD and Thermocouple

- Head Mount Type Temp Transmitter

- Gas Filled Temperature Gauge

- Temprature Instruments

- Higher Range Online Temperature Probe

- Temperature Gauge

- Digital Temp. Controller / Indicator

- Programable Temperature Controller

- Portable Infra-Red Thermometer

- Temperature Transmitter

- Level Instruments

- Magnehelic Gauge

- Flow Instruments

- Pressure Gauges

- Gauge Accessories

- Pressure Switch

- Calibration Instruments

- Data Loggers

- Analog Vacuum Gauge

- Potable Meter

- Air Velocity Sensor

- HVAC Instruments

- Extra Links

- Contact Us

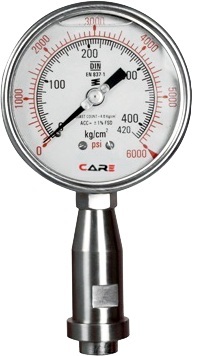

Homogenizer Pressure Gauges

5800 INR/Unit

Product Details:

- Grade Industrial Grade

- Sensor Type Mechanical

- Bourdon Tube Stainless Steel

- Seal Material PTFE

- Outer Size 150 mm

- Thread 1/2 BSP

- Pointer Material Black Anodized Aluminum

- Click to View more

X

Homogenizer Pressure Gauges Price And Quantity

- 5800 INR/Unit

- 1 Unit

- 5800.00 - 5800.00 INR/Unit

Homogenizer Pressure Gauges Product Specifications

- 1/2 BSP

- Polished

- Pressure Relief Valve & Mounting Clamp Included

- 150 mm

- Black Anodized Aluminum

- PTFE

- Mechanical

- Bottom Mount

- Stainless Steel

- 1.0% FSD

- Forged

- High Pressure Fluid (Milk, Juice, etc.)

- Industrial Grade

- 144 mm

- 150 mm

Homogenizer Pressure Gauges Trade Information

- EX-AHMEDABAD

- 1-2 Week

- Meghalaya, Andaman and Nicobar Islands, South India, Central India, East India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Nagaland, Uttarakhand, West Bengal, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Gujarat, Delhi, North India, Kerala, Odisha, West India, Chhattisgarh, Himachal Pradesh, All India

Product Description

With strong tenacity and persistent determination, we endeavor to mark our prominence in manufacturing, supplying and exporting an extensive array ofHomogenizer Pressure Gauges. Having a nominal bit-error-rate, these gauges are widely used in food, chemical, petrochemical and pharmaceutical industries. Post production, our team of quality supervisors checks these gauges on various parameters to ensure their flawlessness. Offered gauges are suitably used for the flow of air, liquids (viscous & semi-viscous) and gases.Homogenizer Pressure Gauges, we offer are high in demand among the clients for the following significant attributes:

- Compact design

- Corrosion & abrasion resistance

- Accurate readout

- Longer service life

- Withstands high pressure

Other details:

- Nominal Size(mm)100,150

- Scale Range0-100 to 0 to 2000kg/cm2

- Accuracy in FSD1%

- Connectionwith/without clamp type / screwed type

- Mounting of GaugeDirect Bottom

- Case and BezelSS 304

- Pressure ElementsBourdon Tube

- DiaphragmNil

- Wetted PartsSS 316,other material on request

- Applicationpharmaceutical, food & beverages, dairy

- OptionalRectangular clamp, Remote capillary, Electric contact & liquid

Specification

|

Dial Size |

4 inch / 100 mm |

|

Dial Type |

Liquid Filled |

|

Display Type |

Analog |

|

Liquid Filling |

Glycerine |

Durable and Reliable Construction

Built for industrial use, the pressure gauge combines a polished stainless steel case with toughened safety glass and EPDM gasket. Its forged processing delivers durability under demanding conditions. With glycerine-filled movement and protection rating of IP65, the gauge resists moisture and mechanical stress.

Precision Monitoring for High Pressure Fluids

Designed for homogenizer machines in dairy and beverage industries, the gauge accurately measures pressure in fluids like milk and juice. The mechanical sensor, stainless steel Bourdon tube, and black anodized aluminum pointer ensure consistent readings even under pressures reaching 1000 Bar.

Versatile Mounting and Safety Features

Suited for both direct and panel mounting (bottom mount), the gauge comes with a pressure relief valve and mounting clamp for secure installation and operational safety. Compliance with CE standards and the use of PTFE seal material ensures leakage prevention and hygienic operation.

FAQs of Homogenizer Pressure Gauges:

Q: How should the Homogenizer Pressure Gauge be installed for optimal performance?

A: The gauge offers both direct and panel mounting options. Ensure secure fitting using the included mounting clamp and connect to the process line via the 1/2 BSP thread at the bottom mount. Position the gauge to provide clear visibility for monitoring and allow for easy access to the pressure relief valve.Q: What fluids can this pressure gauge safely measure?

A: This industrial-grade gauge is suitable for measuring high-pressure fluids such as milk, juice, and other process liquids commonly found in dairy, food processing, and beverage applications. The PTFE seal and stainless steel construction ensure chemical compatibility and safety.Q: When is it necessary to use the pressure relief valve included with the gauge?

A: The pressure relief valve should be used when there is a risk of overpressure exceeding the gauges maximum working limit of 1000 Bar. It acts as a safety mechanism to prevent damage to the gauge and the process system, and should be checked regularly during maintenance.Q: Where is the Homogenizer Pressure Gauge typically installed within processing facilities?

A: This gauge is commonly installed on homogenizer machines or high-pressure lines in dairy, beverage, and food processing plants. It ensures operators have accurate real-time pressure readings to maintain product quality and equipment safety.Q: What routine maintenance processes are recommended for this gauge?

A: Routine maintenance should include visual inspection of the toughened safety glass, checking for leaks at the EPDM gasket and PTFE seals, and ensuring the case is free from corrosion. The glycerine damping fluid should be maintained and the pressure relief valve tested periodically for proper functionality.Q: How does glycerine filling benefit this pressure gauges usage?

A: The glycerine-filled design minimizes effects of vibration and pressure fluctuations, stabilizing the pointer and ensuring accurate readings. This is particularly advantageous in environments with constant pulsations or mechanical movement.Q: What are the advantages of using this gauge in industrial grade applications?

A: This gauge provides high accuracy (1.0% FSD), robust construction, and resistance to harsh operating environments (up to 80C and IP65 protection). Its CE marking assures compliance with safety standards, and the polished finish adds to both durability and professional appearance in industrial settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email